Q.C.M. Fabricating Procedure

*Voice guidance will be played.

*Please note that there is a case that you cannot watch the video due to the types of PC and mobile terminals or browsers’ versions.

*If you cannot watch the video, download from here.

(windows only. wmv file approx. 29.2MB)

Caution ! Plastic section will break if it touches resin monomer.

Selecting the size

Select the proper size so that the flat plastic section covers the buccal curvature of the canines.

- The product code number refers to the length (in mm) of the flat plastic section and is measured from canine to canine.

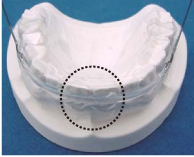

Temporarily fix the plastic labial bow to the cast

Match the midline mark on the plastic with the dental midline of the cast.

Fix the wire temporarily to the cast with cellophane tape.

Never use tape that is too sticky such as duct tape or the plastic section might be discolored by the solvent which is used on such tapes.

3 Applying heat to fit the plastic labial bow

Heat the plastic labial bow with a hair dryer.

The organic polymer will be soft enough to form to the cast with thumb pressure or a soft-tipped blunt tool.

* See the “Choice and Application of Heating Device”, if the results are unsatisfactory.

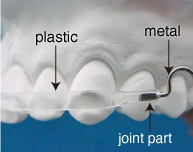

4 Adjusting the angle of the loop

To avoid the loop pressing into the gums, heat the plastic labial bow and then twist the metallic wire a little by hand while pulling it slightly.

* Never grip the plastic section or joint section with pliers etc. when bending the metallic section of the wire.

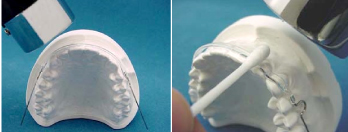

5 Complete the acrylic plate

It is recommended to form clasps, as there will be no chance of the plastic section making contact with the resin monomer. If forming clasps is impossible, incline the palatal side of the cast towards you and then form the acrylic plate carefully by a “brush-on” technique.

* Plastic section will break if it touches resin monomer.

6 Soldering

In order to prevent the metallic wire from conducting heat to the plastic and the acrylic plate, take care to cover the area where the clasps enter the plate and the part around the loop fully with high thermal conductive fixative. The plastic section will melt and catch fire if the flame touches it.

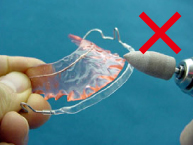

7 Grind the acrylic plate and metallic wire

* Never grind the plastic section. That may cause discoloration or breakage.

* Never clean the plastic part with a concentrated alcohol such as ethanol.

8 Final adiustment

In case the plastic part does not fit the dental arch correctly, reheat the plastic section and refit the dental arch or adjust with the loop.